Many things are happening around DoogieLabs. Once Project that has been in the works for over a year now is my own custom digital instrument cluster that will replace the factory aging cluster currently in the van. (Corrado will be getting one as well but it will be full color)

I have been searching for displays for sometime, I wanted something that could be constructed for a reasonable price.. I considered LCD’s and VFD’s but both has various advantages / disadvantages, then I came across the 8×8 LED matrices and they were just what I needed, uniform and scalable it became clear that I was going to build my own display.

I managed to locate 8×8 Bi-Color LED Matrices (green and red) in a lot of 10 for $15 shipped. To cover the area over cluster opening I had to purchase 3 lots of 10 bringing my cost for the “display material” to just under $50. Remember that with a red/green multicolor LED you can fade the two together for an amber color, giving a nice spectrum for changing readout colors grabbing the drivers attention in the event of an emergency.

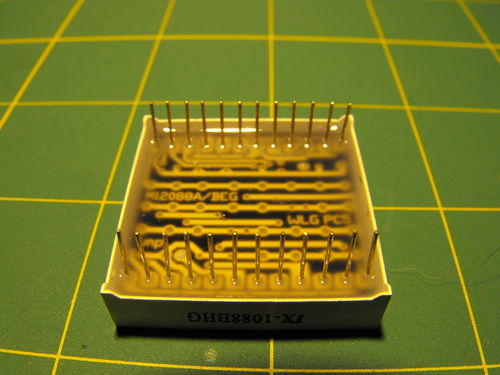

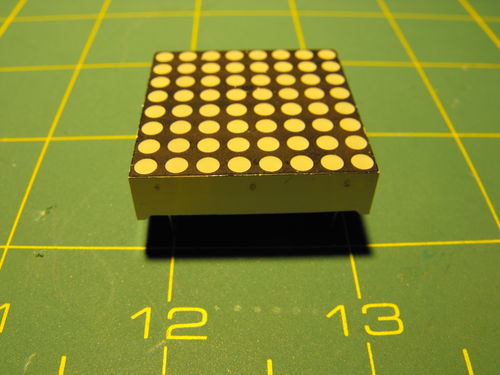

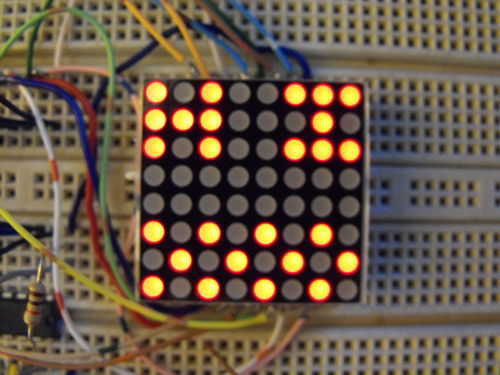

Here is what one matrix looks like:

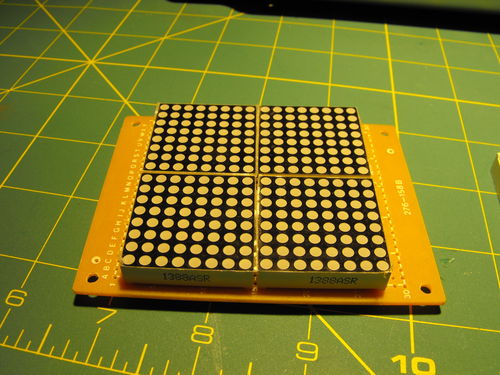

Notice how they are symmetrical on all sides, this allows you to combine them to create a larger uniform display, this picture shows them stuck on some prototyping board to test hole spacing:

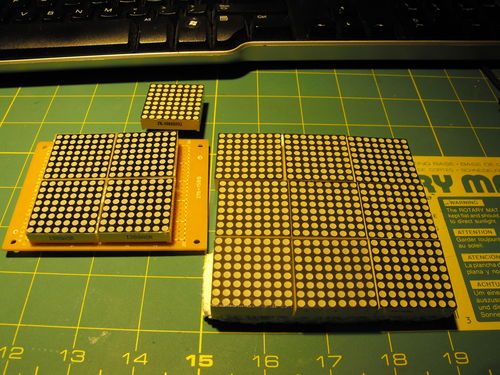

Here is another shot of them grouped together, I plan on having a etched using ExpressPCB’s Service (and free cad software) and will definitely close that 1mm gap in between each matrix (because the ones bunched together on the foam look much better being closer to each other):

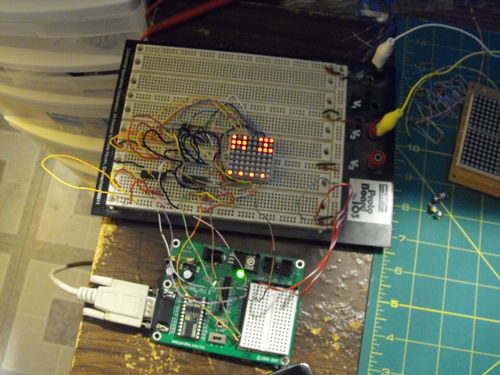

So using my breadboard I quickly cobbled together a circuit to test the display cubes using a basicstamp2:

This is going to work out really nice the brightness should work in near-direct sunlight, I plan on designing the cluster with sunlight in mind (i.e. smoked front cluster face?) so we’ll see how things turn out. Here is the rest of the circuit, at the moment I am using 2 74HC591 shift registers to drive it, leaving the timings up to the basic stamp. I have since ordered a few TLC5941’s to actually drive the display matrices. (which I will definitely be posting more about):

I will create a project page for my cluster in time, because of the “production design” PCB that I plan on ordering that open the door for opportunities at production kits, with enough interest the code can easily be modified to talk with an OBD port for data vs my required Subaru select monitor protocol. Stay tuned as there will be many more updates on this one!

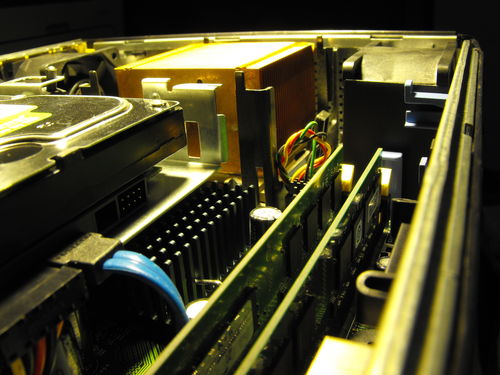

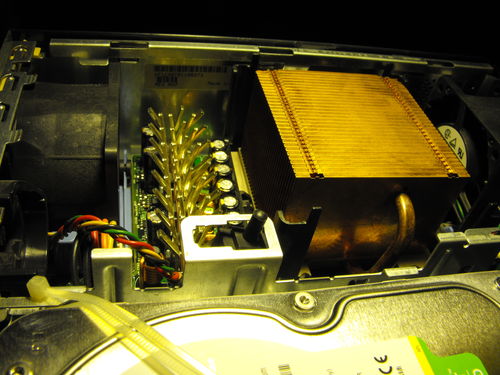

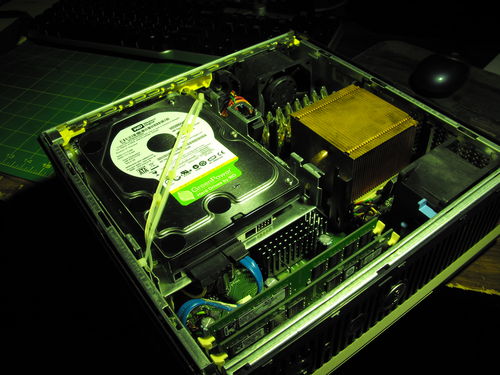

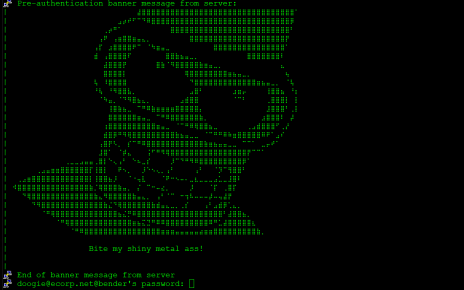

On a side note the server ended up getting dusted out.. Snapped a couple of quick pictures of the crammed insides:

You’ll have to excuse the complicated system of zip-ties as this $10 server didn’t come with a hard drive bracket:

It’s a 3Ghz P4 with hyper-threading, 2GB of ram and 500GB WD Green drive. (slower rpm = cooler running, longer life) It runs SuSE Linux and is very fast, despite not being multi-core.